Case Studies

Project Name: Food Processing Centre

Building Type: Commercial / Industrial

Project Location: PA, USA

Inputs: Full set Design drawings in PDF, 3D models of Architectural, Structural & other services.

Deliverables: Shop drawings, Spool Drawings and Sleeve drawings.

LOD: 400

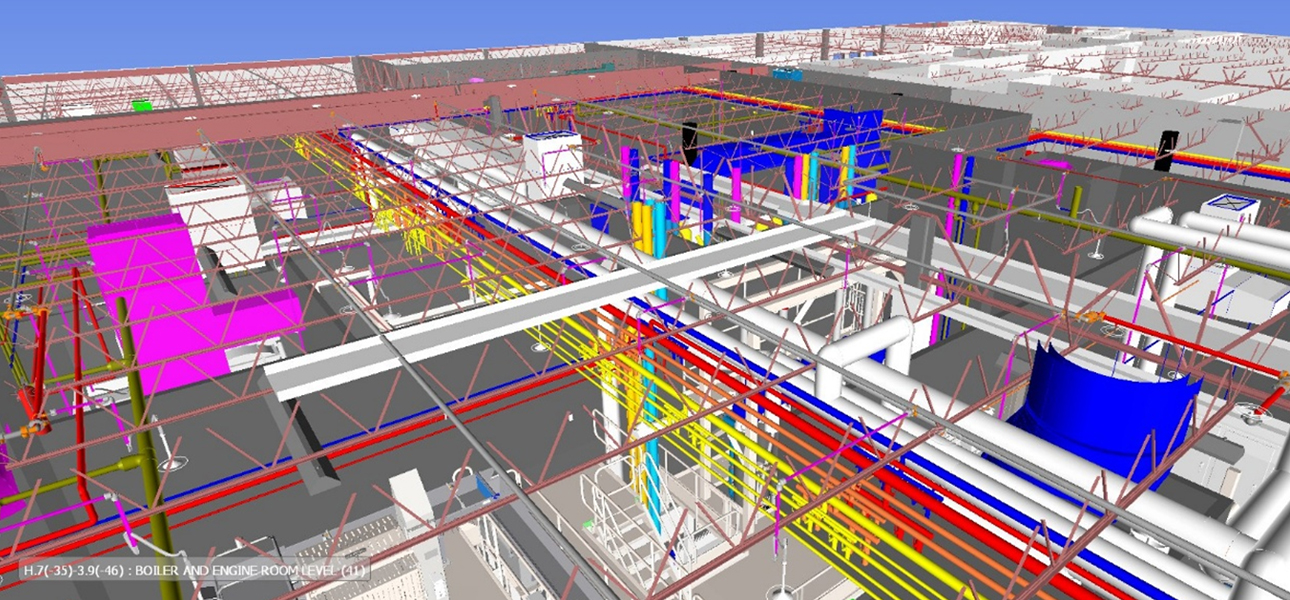

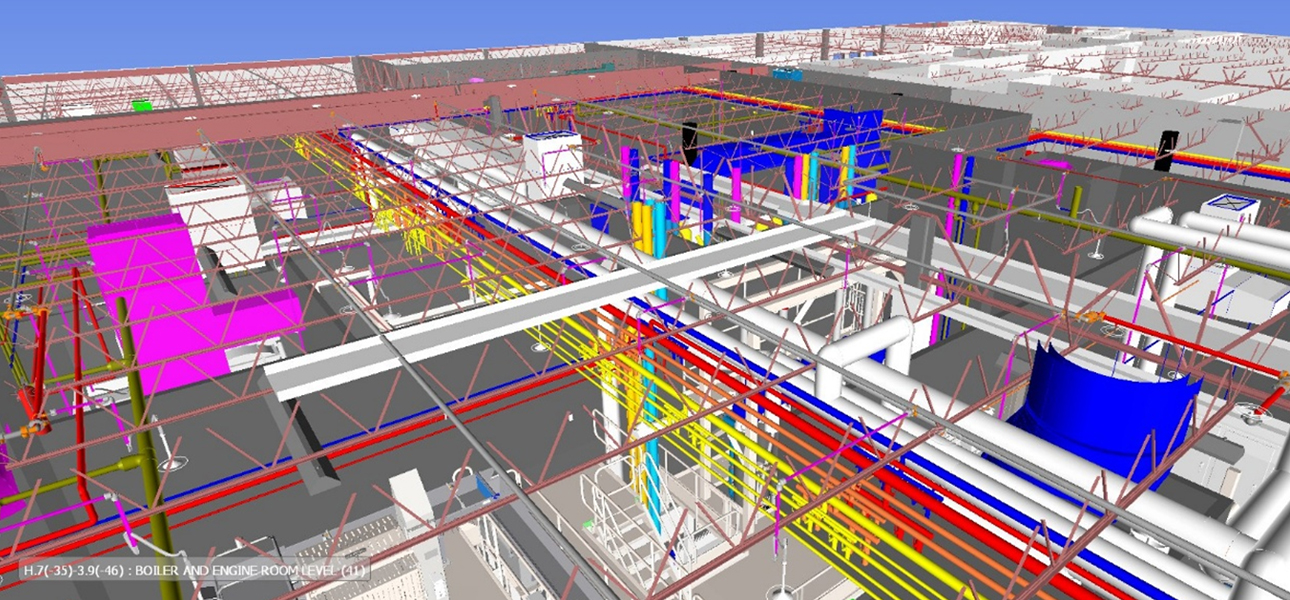

Software: Revit 2024 with Fabrication components, Navisworks Manage 2024

Services: Duct, Mechanical Piping

About the Project

This Design-Build Project represents a significant manufacturing expansion executed in Bethlehem, Pennsylvania, for Freshpet Kitchens. This initiative encompasses a comprehensive renovation of an existing 50,000 square-foot facility and the design and construction of an additional 90,000 square feet of manufacturing and production space—a combined $100 million investment aimed at supporting its growth trajectory and regional economic development.

Scope of work

Our scope of work involved modelling and coordinating the HVAC systems. Utilizing Revit with Fabrication parts, we developed detailed HVAC 3D models, ensuring coordination and clash detection through Navisworks Manage. The design inputs, provided in CAD, and PDF formats, were converted into refined 3D models as per the US standards for seamless coordination. Additionally, architectural, structural & other services 3D models were provided to facilitate comprehensive coordination.

- LOD 400 modelling of HVAC services

- Clash detection & Coordination

- Shop drawings

- Spool fabrication drawings

- Slab penetration drawings

Business Model Adopted

Hourly billing model was adopted for all phase.

Final Deliverables

Our final deliverables comprised the creation of a coordinated set ofHVAC shop drawings, provided in both CAD and PDF formats. Additionally, the deliverables included spool fabrication drawings and Slab penetration drawings.